Ningbo Huali Steel Co., Ltd là nhà sản xuất có tổ chức cao của cuộn hợp kim nhiệt độ cao EN1.4539 tại Trung Quốc. Giá cạnh tranh, chất lượng vượt trội, giao hàng nhanh, mẫu miễn phí, phản ứng nhanh. Liên hệ với chúng tôi để biết các giải pháp tùy chỉnh phù hợp với những gì bạn cần!

EN1.4539 high temperature alloy coil is a low-carbon, highly alloyed austenitic stainless steel, also known as super austenitic stainless steel. Its notable feature is its excellent corrosion resistance, especially in environments containing strong acids such as sulfuric acid and phosphoric acid, as well as corrosive media such as chlorides. By significantly increasing the content of chromium, nickel, molybdenum and copper, 904L stainless steel has shown performance far superior to traditional 304 and 316L stainless steel in a variety of corrosive media.

| GRADE | Chemical Composition | ||||||||

| C | Si | Mn | P | S | Ni | Cr | Mo | Cu | |

| % | % | % | % | % | % | % | % | % | |

| 904L | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.035 | ≤0.03 | 23.0-25.0 | 18.0-20.0 | 3.0-4.0 | 4.0-5.0 |

EN1.4539 high temperature alloy coil has excellent corrosion resistance to both reducing and oxidizing acids, especially in dilute sulfuric acid, acetic acid, formic acid and phosphoric acid. At the same time, its high chromium and molybdenum content significantly improves its ability to resist pitting and crevice corrosion.

The high nickel content gives EN1.4539 high temperature alloy coil excellent resistance to chloride stress corrosion cracking, making it more reliable in marine environments and chloride-containing process media.

Huali Steel's EN1.4539 high temperature alloy coil are precisely controlled and have good welding properties, and can be connected using various conventional welding methods. At the same time, it also has good cold forming and hot forming properties, which is convenient for manufacturing various complex parts.

EN1.4539 high temperature alloy coil has a stable austenitic structure, which avoids the occurrence of sensitization and further improves its long-term performance in corrosive environments.

Even in corrosive environments, EN1.4539 high temperature alloy coil can still maintain good strength and toughness to ensure the stable operation of equipment and structures.

What are applications of EN1.4539 high temperature alloy coil?

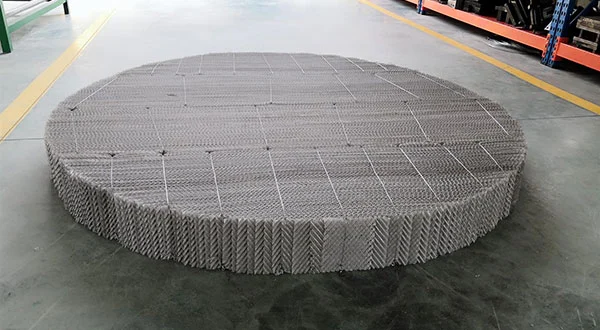

Used to manufacture reactors, storage tanks, pipelines, heat exchangers, agitators, etc., especially suitable for equipment that handles highly corrosive media such as sulfuric acid, phosphoric acid, and acetic acid.

Used in offshore platforms, seawater desalination equipment, transportation pipelines, etc. to resist corrosion in high chloride environments.

Also used in the pharmaceutical industry, environmental protection engineering, pulp and paper industry, food processing industry and other industries.

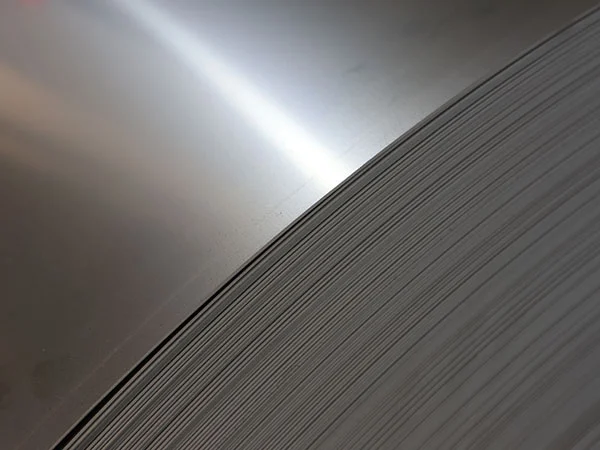

The EN1.4539 high temperature alloy coil has high accuracy, with thickness tolerances as tight as +/-0.002mm. It has 2B, BA, 2BA and more surface finish. The surface we produce are flawless, scratch-free, which it is best choice for applications that demand the highest quality.

Our dedicated loading team ensures meticulous handling of every shipment. Each container is securely reinforced with wood and wire rope to guarantee that your goods ( EN1.4539 high temperature alloy coil) arrive in safe condition.

Certificates: ISO9001, SGS, MTC...